-

WB Aliphatic Isocyanate Prepolymer

WB Aliphatic Prepolymer is designed to be used in water-dispersible formulations. It may be used in many variations of an extremely tough optically clear weather resistant UV stable water-borne coatings. It exhibits excellent durability regarding resistance to abrasion, chemicals and sunlight.

-

Jet Epoxy

Jet Epoxy is a quick set 100% solids self leveling toughened epoxy. It provides excellent adhesive characteristics while exhibiting good chemical, moisture and UV resistance. It can be used as a primer or as a final top-coat. It may be used in confined areas as it emits very low odor emissions. This material is used on metal, wood, fiberglass, concrete, masonry and other difficult to coat surfaces requiring a tough exterior coating. It may also be formulated with anti-corrosion additives to protect ferrous metals from oxidation.

Jet Epoxy may be applied using pressure pot or air-less spray, roll-on or brush-on. This 2K epoxy system finishes glossy smooth when fully cured. This material is to be used directly on clean dry surfaces and becomes tack free within 1 hour depending on ambient humidity and temperature. It is an excellent primer backbone for all SuperSkinSystems’ super-polymers and general topcoats. It retains a wide functional temperature range while yielding good flexibility from 25F to 150F. Full cure is achieved under normal drying conditions in 24 hours.

Jet Epoxy may be applied using pressure pot or air-less spray, roll-on or brush-on. This 2K epoxy system finishes glossy smooth when fully cured. This material is to be used directly on clean dry surfaces and becomes tack free within 1 hour depending on ambient humidity and temperature. It is an excellent primer backbone for all SuperSkinSystems’ super-polymers and general topcoats. It retains a wide functional temperature range while yielding good flexibility from 25F to 150F. Full cure is achieved under normal drying conditions in 24 hours.Jet Epoxy is available in 3 primary formulations:

289: clear and fast

351: low temp fast cure

319: clear slow top coatPlease contact our technical support group for specific substrate application procedures, equipment, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

JointSeal

Joint Seal is a 2-component elastomeric sealing polymer system designed to act as a crack filler primarily in concrete. This material provides exceptional adhesion characteristics and fast cure times. It is highly chemical resistant, insensitive to water, abrasion resistant and remains thermally stable in a range of -20°F (-29 C) to 250°F (125 C). It may be used under traditional floor coatings or any of our top-coating materials. Joint Seal is used in heavy traffic warehouse floors, refrigeration floors, chemical spill prone floors, pothole road repair or under ceramic tile floors. It meets FDA regulations for indirect food contact (CFR 21, Sec. 175-300).

Joint Seal is a 2-component elastomeric sealing polymer system designed to act as a crack filler primarily in concrete. This material provides exceptional adhesion characteristics and fast cure times. It is highly chemical resistant, insensitive to water, abrasion resistant and remains thermally stable in a range of -20°F (-29 C) to 250°F (125 C). It may be used under traditional floor coatings or any of our top-coating materials. Joint Seal is used in heavy traffic warehouse floors, refrigeration floors, chemical spill prone floors, pothole road repair or under ceramic tile floors. It meets FDA regulations for indirect food contact (CFR 21, Sec. 175-300). -

HardSkin

HardSkin is an industrial abrasion resistant spray coating to be used over low density substrates such as polystyrene foam and polyurethane foams which require exterior surface hardnesses up to 70 Shore D. It also provides excellent chemical and moisture resistance and is available with fire retardants to meet E84 Class I. This material is a two component 100% solids and contains no VOCs or solvents. These specialized formulations deliver optimal curing application in very cold or hot climates. HardSkin is paintable and impact resistant.

HardSkin is normally applied by a 2K high pressure plural component pumping machine with hose and primary heat set at 150F. It becomes tack free in 15-20 sec., full cure in 48 hrs. and delivers a functional temperature range of -20F to 200F. This material may also be applied by hand-held cartridge gun used at room temperature.

Please contact our technical support group for specific substrate application procedures, equipment, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

GlowSkin

GlowSkin is a durable long-lasting glow-in-the-dark harsh environment coating used primarily in safety applications providing dark dangerous areas a strong nite-light. When fully charged by the sun or auxiliary lights, the nite-light GlowSkin lasts brilliantly for 2 hours. This material is embodied ClearSkin which delivers an extremely tough weather resistant coating. It exhibits excellent durability regarding resistance to abrasion, chemicals and sunlight. Being very tough, it is used primarily in exterior high-wear environments where severe topcoat protection is required. Although GlowSkin may be used directly on many types of surfaces, it is normally used over a reflective base-coat color such as white, yellow or silver to add more to the reflective-glow. GlowSkin top-coat is available in Green and Blue. Mixing together gives a gentle aqua or light teal.

GlowSkin is a very intense high-performance glow material used in military ships, transportation subways and tunnels, amusement parks, parking decks, office building stairwells, boat docks and the art world. It provides excellent adhesive characteristics and can withstand arctic freezing or desert hot conditions.

GlowSkin is a very intense high-performance glow material used in military ships, transportation subways and tunnels, amusement parks, parking decks, office building stairwells, boat docks and the art world. It provides excellent adhesive characteristics and can withstand arctic freezing or desert hot conditions.Please contact our Customer Service and Technical Support Group for any questions or to provide direction with specific selection of a material system, questionable target surfaces, operational procedures, material pumping/spray machines, spray/pour guns, safety protection gear and clean-up kits. Please refer to MSDS for material safety information.

-

I-Skin Foam

I-Skin Foam (Integral-Skin) is a high performance self-skinning foam designed for toughness and durability. Its hardness ranges from semi-rigid to sponge-soft to provide for multi-versatile applications such as commercial impact floor mats, seating cushions, vibration insulators, rigid impact panels, sports equipment, soft/rigid play toys, etc. It may be formulated in any color and many densities to accommodate very specific requirements.

This unique foam exhibits very low compression set while providing dimensional stability through its wide operating temperature range. I-Skin Foam is formulated from special MDI prepolymers to create very fast molding cycles. It is available using water or gas blown formulations. I-skin can also be formulated to meet CAL 117, MVSS 302 and FAR 25.853a

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

FireSkin 1K

FireSkin™ 1K is a high temperature waterborne intumescent fire-resistant barrier coating that will withstand direct flame contact. It does not emit continuous smoke with E84 testing yielding 5=flame spread and 70=smoke during flame exposure. It is environmentally friendly and is used in demanding fire shielding applications such as mine safety, protecting steel frameworks, building foam insulation, utility poles, cedar shake roofs, styrene and polyurethane foam board and other flammable material protection. Designers also use this material’s unique decorative coating properties to enhance interior walls specified by fire-retardant requirements as acrylic texture chips may be added. 1K FireSkin also provides outstanding UV stability.

It is a water-based formulation that is applied by low pressure air-less spray equipment, roller or brush. It is non-toxic and and may be appled in low-ventilated enclosed areas. Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

It is a water-based formulation that is applied by low pressure air-less spray equipment, roller or brush. It is non-toxic and and may be appled in low-ventilated enclosed areas. Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.GlowSkin is capable of being added to Fireskin 1K.

-

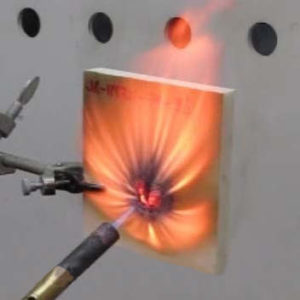

FireSkin™ Foam

FireSkin Foam is an insulating material designed to withstand direct flame contact. It produces very low smoke and flame spread. The material develops an intumescent fire barrier which provides a protective shield against constant flame and extreme heat conduction to interior surfaces. These closed cell foams range in varing densities from 0.5-50 pcf for use in diverse fire protection system applications. FireSkin Foam is formulated as a Halogen-free, Class 1 fire rated foam containing renewable resource “Green” materials.

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here.

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here. -

FireSkin™ 2K

FireSkin 2K super-polymer is an insulating microcellular polymeric material that will withstand direct flame contact. It emits low smoke and flame spread during flame exposure making it a valuable resource for diverse fire protection enclosure applications.

FireSkin 2K super-polymer is an insulating microcellular polymeric material that will withstand direct flame contact. It emits low smoke and flame spread during flame exposure making it a valuable resource for diverse fire protection enclosure applications.It has been specially designed to coat polyurethane and polystyrene foams for fire protection. Other uses include protecting buildings, humans, animals and all nature against the destructive force of fire. Uses include deployable fire barrier systems, mobile structures, hazardous containers and specialily shielding systems for schools and apartments.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

Decorative TextureCoat™

Decorative TextureCoat™ (DTC) is a tough weather resistant UV stable protective coating. It presents a decorative stucco-like texture finish which exhibits excellent durability and resistance to high wind abrasion, chemicals, staining and sunlight. This coating demonstrates a combination of many unique characteristics exhibiting excellent adhesion and penetrating capabilities securing a high performance bond to substrate. Decorative color texturing chips give this single component sprayable material a wide range of styling effects. This waterproofing exterior tough-coat may be used over diverse types of substrates such as existing stucco, concrete, brick, stone, metal, wood and composites.

Decorative TextureCoat™ (DTC) is a tough weather resistant UV stable protective coating. It presents a decorative stucco-like texture finish which exhibits excellent durability and resistance to high wind abrasion, chemicals, staining and sunlight. This coating demonstrates a combination of many unique characteristics exhibiting excellent adhesion and penetrating capabilities securing a high performance bond to substrate. Decorative color texturing chips give this single component sprayable material a wide range of styling effects. This waterproofing exterior tough-coat may be used over diverse types of substrates such as existing stucco, concrete, brick, stone, metal, wood and composites.DTC is used as a waterproofing exterior topcoat sealer. DTC spray coating maintains good flexibility in severe hot and cold environments. It’s surface skin may be ultra-fine to medium to coarse. It is commonly used for face-lifting stucco and painted surfaces. It may also be mixed with other aggregates such aluminium oxide, walnut shells or fine stone creating anti-skid and finely styled decorative surfaces. See color textures chart for standard color blends.

Decorative TextureCoat™ is a high performance aliphatic coating with very low ordor during application. Color pigments and textures may also be added as desired. This material may also be applied directly to urethane foam materials in such applications as exterior artwork, architectural moldings or decorative facial panels.

-

Cushion Foam

Cushion Foam is a superior bio-based flexible microcellular open-cell foam designed to deliver very high toughness and durability for diverse fields of application such as furniture seating cushions, automotive seating, house-wraps, play toys, shock and vibration absorption, impact sports padding, sound-proofing, etc. Seating densities normally range from 3-5 pcf. Density formulations may be adjusted to accommodate other very specific requirements including colors.

This unique bio-based high resilient (HR) flexible foam exhibits very low compression set while providing dimensional stability through its wide operating temperature range. Cushion Foam is formulated from special MDI pre-polymers to create very fast production and de-molding cycles.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.