-

5000-2.5 TRX Pouring Foam

5000-2.5 TRX pouring foam is a water-blown foam designed especially for pour casting into molds to create very intricate very diverse parts. This pouring foam is blended to specifically designed re-activity molding times such as creme time, gel time, tack-free and overall cure time. The foam contains a bio-based polyol. This pour casting foam may be used in a variety of applications in very diverse industries such as architectural wall and decorative part moldings, furniture and toy markets, specialty part moldings etc.

Please contact our Customer Service and Technical Support Group for any questions or to provide direction with specific selection of a material system, questionable target applications, operational procedures, material pumping/pour machines, safety protection gear and clean-up.

-

70D Casting Resin

Casting Resin 70 is specifically formulated 2-component 100% solids polyurea-based materials designed to produce dimensionally stable, chemical resistant parts. This material may be pour cast, RIM injected molded or cartridge gun spray dispensed. Cured parts exhibit hardness of 70 D, excellent physical durability and chemical resistance. Casting Resin 70 reactivity is very fast with a 1-2 minute gel for fast manufacturing part cycle times obtaining full cure within 24 hours. Material shrinkage is 1%. Fillers may be added to reduce shrinkage and to provide other desired physical properties. Pigments are normally added to provide uniform appearance. Material functional operation temperature ranges from -20°F to 250°F.

Casting Resin 70 is specifically formulated 2-component 100% solids polyurea-based materials designed to produce dimensionally stable, chemical resistant parts. This material may be pour cast, RIM injected molded or cartridge gun spray dispensed. Cured parts exhibit hardness of 70 D, excellent physical durability and chemical resistance. Casting Resin 70 reactivity is very fast with a 1-2 minute gel for fast manufacturing part cycle times obtaining full cure within 24 hours. Material shrinkage is 1%. Fillers may be added to reduce shrinkage and to provide other desired physical properties. Pigments are normally added to provide uniform appearance. Material functional operation temperature ranges from -20°F to 250°F. -

Aliphatic Prepolymers (APU Series)

The APU Series is a new family of HDI aliphatic prepolymers using polyurea technology. All prepolymers are monomer extracted to levels of 0.1%. The prepolymers are available from 6% to 20% NCO. Specifically designed or custom Prepolymers may be manufactured for client needs. All prepolymers are 100% solids. These prepolymers may be supplied with solvents upon request. The APU # indicates the % NCO. APU-16 is one our standard workhorse prepolymers in polyurea formulations and well as in the polyaspartic series of products to deliver specific performances.

-

Anti-Graffiti Coating

Anti-Graffiti coating represents a new class of tough thin and durable advanced polymers. This easy to apply coating turns ordinary walls and ceilings into a cleanable canvas of art. It’s unique physical properties give it superior cleanability and resistance to Sharpie solvent markers and most paints. Universal rubbing alcohol is used as the cleaner fluid with a dry clean rag. The Anti-Graffiti Coating is used on school room walls to replace blackboards and dry erase boards, subway walls and ceilings to provide easier paint removal, hospital walls and floors to enable easy clean up sanitary surfaces, protect outdoor building walls, steel and concrete bridges members, public bathroom walls and any surface indoor or out which requires graffiti protection or to aid in cleaning.

This 70% solids 2-component coating is water based and therefore is easy to clean up using soap and water. It is easily applied using roller, air-less spray machine or brush. Pot life after mixing is 30 minutes with air dry tack free surface time of 45 minutes depending on ambient humidity. It may be formulated in just about any color or clear as its natural state. It exhibits a high functioning temperature of 220°F, excellent abrasion and outdoor UV stability. It remains flexible at 0°F and can withstand light mild solvent attack. Given this materials extraordinary clean-ability and durability characteristics it lends itself to many diverse demanding applications.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

APA

APA is a new revolutionary, zero VOC, non-conventional exterior, 100% polyurea coating. This product has been designed specifically to deliver the toughness and abrasion resistant properties of that of an aromatic polyurea but provides the capability of retaining color-fastness for a full range of pigmented colors. Unlike conventional aromatic polyurea, which in a white pigmented system turns yellow in hours when left in direct sun light, APA systems can withstand direct harsh sunlight experiencing no color change after 1 year. APA is available with different hardness and reactivities. APA is available in 2 versions – horizontal and vertical. Horizontal APA has a gel time of approximately 30-45 seconds allowing the ability to broadcast into it if desired, whereas Vertical APA is a quick set material allowing to be sprayed vertically without running. APA has excellent adhesion properties allowing it to be sprayed on all types of surfaces including spray foams. APA complies with FDA 21CFR 175.105 and 21 CFR 175.300. APA is also available with fire retardant additives. These additives allow APA to meet ASTM E84 Class A. APA uses a mix ratio of 1A – 1B. APA may be applied using high pressure heated plural equipment, low pressure heated equipment or using cold spray 2K cartridge equipment. Recommended heater settings are 140°F for both primary heaters and hose heater. Machine pressure should be set at around 2000 psi.

-

BallisticSkin™ Polyurea

BallisticSkin™ super-polymer technologies are designated into 3 groups: BS-NEAT, BS-LAM and BS-SM. BS-NEAT may be cast optically clear to a thickness of 1.25″ (31mm) to handle intense hand gun fire at close range with fire-power from multiple rounds of 44 magnum, 9 mm and 45 caliber bullets. As shown in shown Fig. 1 a couple of 45 caliber bullets were stopped at a depth of .375″ into BS-NEAT at close range. BS-LAM is specificially designed for composite builds using numerous inner members such as ultra hard steels, ceramics, kevlar fabrics and ultra-dense engineered thermoplastics. BS-SM is an ultra tough energy absorbing skin used primarily in shrapnel mitigation.

BallisticSkin super-polymer materials are capable of absorbing very high impact energy, extremely high tear resistance and can withstand high heat capacities whereby demonstrating ultimate toughness. The spray version of BallisticSkin (BS-SM) is used to strengthen a variety of military grade substrates used for tranportation vehicles, armorment assemblies and structural building reinforcement as shown in Fig. 2 where BS-SM is sprayed on a high strength very hard steel (Brinnel 60-65) panel at a thickness of 3.6 mm. Shown from the back side, the left hand side shows the dark green BS-SM super-polymer coating strenghthening the hard steel keeping it from shattering into shrapnel and panel failure cracking.

Generally, BallisticSkin™ super-polymers are used in some type of ballistic shielding applications. These materials may be applied to many types of structural substrates which include high strength steel, 6061 Aluminum, high-strength composites, wood laminates, reinforced masonry and concrete. These unique materials provide extreme protection for safe-houses, personnel vehicles, government buildings, armed outposts and special aircraft. For specific applications, please contact our technical support group.

Sprayed samples must be aged 30 days at room temperature prior to shooting.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

BlastSkin II – Mine Safety

BlastSkin II- Mine Surface Protection System is a very strong super-polymer coating system designed to provide structural support while shielding against water and methane infiltration for all surfaces in the mine. This system provides high chemical, abrasion resistance, low fire and smoke meeting Class 1 ASTM E84, MSHA ASTM E162, Radiant Panel testing and MSHA IC-249 Flame resistance of solid products. The BlastSkinII protection system effectively delivers increases load bearing capacity and reduces localized failure points to defend against rupture and bursting. This high-strength composite structure provides added protection to mine workers, framework infrastructure and overall mine safety.

Mine Surface Protection System:

- Inject LeakStop into all surface cracks and voids.

- Spray structural FireSkin™ Foam (10 pcf) on mine surfaces (25mm).

- Apply BlastSkinII super-polymer over the structural FireSkin Foam (3mm to 6mm).

- Apply GlowSkin striping to walls (0.5mm).

-

BlastSkin™

BlastSkin™ polyurea is a high strength energy absorbing super-polymer designed to deliver extensive elastomeric resiliency when subjected to explosive energy forces. This military grade formulation possess extremely high material tear strengths, exceptional abrasion and superior toughness. When subjected to an exothermic explosion, the super-polymer’s molecular geometry is pushed to a very high energy state enabling it to absorb the kinetic energy of the blast’s shock wave. It will provide containment of its underlying fractured substrate peventing the debris of shrapnel fragments. Military testing has demonstrated blast pressure rates in the order of 250 psi/ms performance at 0.25″ thickness. See BlastSkin Test Blast Movie

BallisticSkin™ is constructed as a NEAT super-polymer or as a composite fabrication. Material thicknesses of the super-polymers are dictated by the requ ired level of protective performance along with application specific required substrates. Typical material substrates include very high strength steel, 6061 Aluminum, UHMW engineering polymers, fabric composites, ceramics, masonry and concrete. Please contact our technical support group for specific substrate application procedures, spray machines, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

Casting Resins

Casting Resins are specifically formulated as 2-component 100% solids polyurea-based materials designed to produce dimensionally stable high temperature, high impact, chemical resistant parts. Resins are available in both hard or flexible versions and provide a dent-scratch resilient class A part surface. Flexible Casting Resin may be pour cast, RIM injected molded or cartridge gun spray dispensed. Cured materials are extremely tough and exhibit excellent durability against abrasion and cleaning chemicals. Casting Resins deliver a 1-15 minute reaction time to provide enhanced part manufacturing cycle times. Depending on the hard or semi-flexible neat formulation the material shrinkage will range from .007-.010 in./lin. in. Fillers may be added to reduce shrinkage and to provide other desired physical properties. Pigments are normally added to provide uniform appearance. Material functional operation temperature ranges from -40°F to 180°F.

-

ChemEpoxy

ChemEpoxy is a versatile fast low-temperature curing Novalac epoxy with excellent chemical resistance such as resistance to 98% sulfuric and 37% HCL acids. It provides superior resistance to water spotting, even under adverse conditions, and is DOT noncorrosive. This material is used in industrial flooring, chemically resistant tank linings, chemical handling equipment, chemical storage vessels and marine environments. It is used on metal, wood, fiberglass, concrete, masonry and other difficult to coat low temperature surfaces requiring a tough chemical resistant coating.

ChemEpoxy is a versatile fast low-temperature curing Novalac epoxy with excellent chemical resistance such as resistance to 98% sulfuric and 37% HCL acids. It provides superior resistance to water spotting, even under adverse conditions, and is DOT noncorrosive. This material is used in industrial flooring, chemically resistant tank linings, chemical handling equipment, chemical storage vessels and marine environments. It is used on metal, wood, fiberglass, concrete, masonry and other difficult to coat low temperature surfaces requiring a tough chemical resistant coating.ChemEpoxy is 2-component mixture which may be applied using roller, brush or low-pressure pot spray. This material is to be used directly on clean dry contaminant-free surfaces and becomes tack free within 1 hour depending on ambient humidity and temperature. Full cure is achieved under normal drying humidity in 7 days at ambient temperature.

Please contact our technical support group for specific substrate application procedures, equipment, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

ChemSkin™ Polyurea

ChemSkin is an extremely tough, 100% solids, super-polymer formulations which stands up to high heat and provides excellent chemical resistance. ChemSkin provides excellent bonding performance, low surface friction, toughness and abrasion resistance. This unique super-polymer is designed to be applied as a fast-set spray with gel time of approximately 5-10 seconds. ChemSkin is available with flame retardants upon request. ChemSkin is a naturally caramel colored translucent coating which can be color tinted to produce translucent or opaque colors. This aromatic super-polymer is not UV stable and must be top coated with an aliphatic UV stable coating.

-

ClearSkin

Clearskin is a 100% solid aliphatic roll on coating. There are two versions available as roll on.

- 12-15 minute pot life and set to touch in 30 minutes.

- 1 hour pot life and 45 minutes set to touch.

Both produce a clear hard high gloss coating. Both 1&2 can be supplied in colors and both have excellent chemical and UV resistance. #1 has been found to have excellent electrical properties. 16 mils of coating can resist 10000 volts. Making it a great insulator.

Clearskin makes an excellent coating for steel, concrete, wood and marine applications. Its ability to cure fast with no VOCs reduces downtime to return to service. Clearskin has excellent water and chemical resistance to meet any condition. Clearskin is optically clear but can be pigmented and can have anti-corrosive additives if needed.

-

Continuous Panel Laminator

SuperSkinSystems has developed a continuous foam panel laminating machine to produce foam boards for a variety of applications. This machine technology combined our foam chemistry technology may accommodate board stock widths as wide as desired utilizing multiple dispensing heads and increased conveyor units heads continuous 30″ wide board stock which may incorporate a host of outer skin materials and inner reinforcement materials sandwiched together using our RigidBuildingFoams or FireSkinFoams. These matrix foaming core materials may also be Bio-based and available in densities ranging from 2-30 pcf. The outer skins of the continuous panel may include a wide range of materials such as cardboard, wood, plastics, canvas, fabrics, metals and woven reinforcement cloths. Inner laminate materials such as Basalt, S-glass, Carbon or Kevlar fibers may also be incorporated into the panel to be used as structural reinforcements. Panels lengths may be cut to any size and widths may be narrowed down to just a few inches for specialized applications. Panels thickness may range from 0.25-4.0 inches.

Click here to view full model Decorative Panels may be achieved by color top-coating and sequential color texturing. Panels may be secondary coated with any SuperSkinSystems materials for desired specifications. Structural Panels used in flooring applications may be coated with our Non-Skid system or coated with our high dielectric coating to arrest electrical conduction. These lightweight very high strength panels utilize non-hydroscopic foaming cores to allow for exterior use. Typical panel uses include floors, walls, ceilings, roofs, exterior signage, decorative interior design, displays, furniture, structural reinforcing spars, boat transoms, firewalls, shielding, etc.

Given the diversity of materials which may be integrated into this Panel Composite and/or the selection of applied high-performance exterior coatings, these panels offer extraordinary characteristics which lends themselves into many diverse and demanding applications. For assistance in the selection of a panel construction and its application, please call or email our Technical Support Group.

-

Cushion Foam

Cushion Foam is a superior bio-based flexible microcellular open-cell foam designed to deliver very high toughness and durability for diverse fields of application such as furniture seating cushions, automotive seating, house-wraps, play toys, shock and vibration absorption, impact sports padding, sound-proofing, etc. Seating densities normally range from 3-5 pcf. Density formulations may be adjusted to accommodate other very specific requirements including colors.

This unique bio-based high resilient (HR) flexible foam exhibits very low compression set while providing dimensional stability through its wide operating temperature range. Cushion Foam is formulated from special MDI pre-polymers to create very fast production and de-molding cycles.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

Decorative TextureCoat™

Decorative TextureCoat™ (DTC) is a tough weather resistant UV stable protective coating. It presents a decorative stucco-like texture finish which exhibits excellent durability and resistance to high wind abrasion, chemicals, staining and sunlight. This coating demonstrates a combination of many unique characteristics exhibiting excellent adhesion and penetrating capabilities securing a high performance bond to substrate. Decorative color texturing chips give this single component sprayable material a wide range of styling effects. This waterproofing exterior tough-coat may be used over diverse types of substrates such as existing stucco, concrete, brick, stone, metal, wood and composites.

Decorative TextureCoat™ (DTC) is a tough weather resistant UV stable protective coating. It presents a decorative stucco-like texture finish which exhibits excellent durability and resistance to high wind abrasion, chemicals, staining and sunlight. This coating demonstrates a combination of many unique characteristics exhibiting excellent adhesion and penetrating capabilities securing a high performance bond to substrate. Decorative color texturing chips give this single component sprayable material a wide range of styling effects. This waterproofing exterior tough-coat may be used over diverse types of substrates such as existing stucco, concrete, brick, stone, metal, wood and composites.DTC is used as a waterproofing exterior topcoat sealer. DTC spray coating maintains good flexibility in severe hot and cold environments. It’s surface skin may be ultra-fine to medium to coarse. It is commonly used for face-lifting stucco and painted surfaces. It may also be mixed with other aggregates such aluminium oxide, walnut shells or fine stone creating anti-skid and finely styled decorative surfaces. See color textures chart for standard color blends.

Decorative TextureCoat™ is a high performance aliphatic coating with very low ordor during application. Color pigments and textures may also be added as desired. This material may also be applied directly to urethane foam materials in such applications as exterior artwork, architectural moldings or decorative facial panels.

-

EpoxyInjection

EpoxyInjection is a 2-component, 100% solids, toughened low-viscosity epoxy injection formulation specifically designed for in-place resin injection for cracked concreted structures such as dams, locks, canals, power plants, water reservoirs, water treatment facilities, foundations, parking garages, aqueducts, etc. This low viscosity epoxy is pumped into holes and cracks to create waterstops in weakened concrete infrastructure systems. It provides excellent adhesive characteristics while exhibiting good chemical resistance, water infiltration and exfiltration resistance. It exhibits low odor emissions, 0% VOCs, long working time, excellent cure at low temperatures and high humidities, superior hardness and low viscosity for high-penetrating injection. This material will bond to concretes, masonary and metals.

Epoxy Injection may be applied using plural component mixing pumping systems or conventional pressure pot/mix systems at a 2:1 dispensing ratio. This 2K epoxy injection material adds strength or structrual preservation to the concrete system when fully cured. Its cure times may be adjusted for specific difficult applications. It conforms to ASTM C-881, Types I, II, IV adhesive, Grade-1, Class C and AASHTO M-235 specifications.

Please contact our technical support group for specific substrate application procedures, equipment, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

FireSkin 1K

FireSkin™ 1K is a high temperature waterborne intumescent fire-resistant barrier coating that will withstand direct flame contact. It does not emit continuous smoke with E84 testing yielding 5=flame spread and 70=smoke during flame exposure. It is environmentally friendly and is used in demanding fire shielding applications such as mine safety, protecting steel frameworks, building foam insulation, utility poles, cedar shake roofs, styrene and polyurethane foam board and other flammable material protection. Designers also use this material’s unique decorative coating properties to enhance interior walls specified by fire-retardant requirements as acrylic texture chips may be added. 1K FireSkin also provides outstanding UV stability.

It is a water-based formulation that is applied by low pressure air-less spray equipment, roller or brush. It is non-toxic and and may be appled in low-ventilated enclosed areas. Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

It is a water-based formulation that is applied by low pressure air-less spray equipment, roller or brush. It is non-toxic and and may be appled in low-ventilated enclosed areas. Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.GlowSkin is capable of being added to Fireskin 1K.

-

FireSkin™ 2K

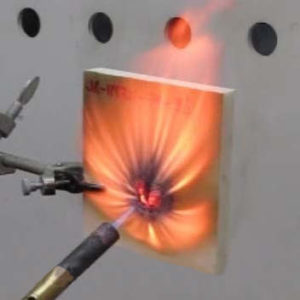

FireSkin 2K super-polymer is an insulating microcellular polymeric material that will withstand direct flame contact. It emits low smoke and flame spread during flame exposure making it a valuable resource for diverse fire protection enclosure applications.

FireSkin 2K super-polymer is an insulating microcellular polymeric material that will withstand direct flame contact. It emits low smoke and flame spread during flame exposure making it a valuable resource for diverse fire protection enclosure applications.It has been specially designed to coat polyurethane and polystyrene foams for fire protection. Other uses include protecting buildings, humans, animals and all nature against the destructive force of fire. Uses include deployable fire barrier systems, mobile structures, hazardous containers and specialily shielding systems for schools and apartments.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

FireSkin™ Foam

FireSkin Foam is an insulating material designed to withstand direct flame contact. It produces very low smoke and flame spread. The material develops an intumescent fire barrier which provides a protective shield against constant flame and extreme heat conduction to interior surfaces. These closed cell foams range in varing densities from 0.5-50 pcf for use in diverse fire protection system applications. FireSkin Foam is formulated as a Halogen-free, Class 1 fire rated foam containing renewable resource “Green” materials.

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here.

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here. -

FireSkin™ Foam 0.5

Fireskin Foam 0.5 is a two component, 1-1 parts by volume, light density, spray applied polyurethane foam. To produce Fireskin Foam 0.5 requires the use of an A-Component (ISO) and a B-Component (RESIN), which contains zero ozone depleting blowing agents, catalyst, polyols and flame-retardant materials such as fiberglass, cellulose or other loose fill products. Typical areas where spray polyurethane foam is applied are interior walls, attics, ceilings and spa insulations.

-

GlowSkin

GlowSkin is a durable long-lasting glow-in-the-dark harsh environment coating used primarily in safety applications providing dark dangerous areas a strong nite-light. When fully charged by the sun or auxiliary lights, the nite-light GlowSkin lasts brilliantly for 2 hours. This material is embodied ClearSkin which delivers an extremely tough weather resistant coating. It exhibits excellent durability regarding resistance to abrasion, chemicals and sunlight. Being very tough, it is used primarily in exterior high-wear environments where severe topcoat protection is required. Although GlowSkin may be used directly on many types of surfaces, it is normally used over a reflective base-coat color such as white, yellow or silver to add more to the reflective-glow. GlowSkin top-coat is available in Green and Blue. Mixing together gives a gentle aqua or light teal.

GlowSkin is a very intense high-performance glow material used in military ships, transportation subways and tunnels, amusement parks, parking decks, office building stairwells, boat docks and the art world. It provides excellent adhesive characteristics and can withstand arctic freezing or desert hot conditions.

GlowSkin is a very intense high-performance glow material used in military ships, transportation subways and tunnels, amusement parks, parking decks, office building stairwells, boat docks and the art world. It provides excellent adhesive characteristics and can withstand arctic freezing or desert hot conditions.Please contact our Customer Service and Technical Support Group for any questions or to provide direction with specific selection of a material system, questionable target surfaces, operational procedures, material pumping/spray machines, spray/pour guns, safety protection gear and clean-up kits. Please refer to MSDS for material safety information.

-

Ground Glass Powder

SSS Ground Glass Powder is made from 100% recycled glass occurring in laminated glass (primarily automotive windshields). The product is gray colored powder with a uniform particle size distribution. SSS Ground Glass Powder is amorphous and contains no crystalline silica and provides a clean post-consumer filler for polymer-based systems. This filler impart excellent abrasion resistance and chemical stability to coatings and other polymer systems. SSS Ground Glass Powder processing system provides consistent product quality with fineness covering a range of potential applications. Product is screened and shows average size particles of Mesh 325.

-

HardSkin

HardSkin is an industrial abrasion resistant spray coating to be used over low density substrates such as polystyrene foam and polyurethane foams which require exterior surface hardnesses up to 70 Shore D. It also provides excellent chemical and moisture resistance and is available with fire retardants to meet E84 Class I. This material is a two component 100% solids and contains no VOCs or solvents. These specialized formulations deliver optimal curing application in very cold or hot climates. HardSkin is paintable and impact resistant.

HardSkin is normally applied by a 2K high pressure plural component pumping machine with hose and primary heat set at 150F. It becomes tack free in 15-20 sec., full cure in 48 hrs. and delivers a functional temperature range of -20F to 200F. This material may also be applied by hand-held cartridge gun used at room temperature.

Please contact our technical support group for specific substrate application procedures, equipment, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

I-Skin Foam

I-Skin Foam (Integral-Skin) is a high performance self-skinning foam designed for toughness and durability. Its hardness ranges from semi-rigid to sponge-soft to provide for multi-versatile applications such as commercial impact floor mats, seating cushions, vibration insulators, rigid impact panels, sports equipment, soft/rigid play toys, etc. It may be formulated in any color and many densities to accommodate very specific requirements.

This unique foam exhibits very low compression set while providing dimensional stability through its wide operating temperature range. I-Skin Foam is formulated from special MDI prepolymers to create very fast molding cycles. It is available using water or gas blown formulations. I-skin can also be formulated to meet CAL 117, MVSS 302 and FAR 25.853a

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

Jet Epoxy

Jet Epoxy is a quick set 100% solids self leveling toughened epoxy. It provides excellent adhesive characteristics while exhibiting good chemical, moisture and UV resistance. It can be used as a primer or as a final top-coat. It may be used in confined areas as it emits very low odor emissions. This material is used on metal, wood, fiberglass, concrete, masonry and other difficult to coat surfaces requiring a tough exterior coating. It may also be formulated with anti-corrosion additives to protect ferrous metals from oxidation.

Jet Epoxy may be applied using pressure pot or air-less spray, roll-on or brush-on. This 2K epoxy system finishes glossy smooth when fully cured. This material is to be used directly on clean dry surfaces and becomes tack free within 1 hour depending on ambient humidity and temperature. It is an excellent primer backbone for all SuperSkinSystems’ super-polymers and general topcoats. It retains a wide functional temperature range while yielding good flexibility from 25F to 150F. Full cure is achieved under normal drying conditions in 24 hours.

Jet Epoxy may be applied using pressure pot or air-less spray, roll-on or brush-on. This 2K epoxy system finishes glossy smooth when fully cured. This material is to be used directly on clean dry surfaces and becomes tack free within 1 hour depending on ambient humidity and temperature. It is an excellent primer backbone for all SuperSkinSystems’ super-polymers and general topcoats. It retains a wide functional temperature range while yielding good flexibility from 25F to 150F. Full cure is achieved under normal drying conditions in 24 hours.Jet Epoxy is available in 3 primary formulations:

289: clear and fast

351: low temp fast cure

319: clear slow top coatPlease contact our technical support group for specific substrate application procedures, equipment, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

JointSeal

Joint Seal is a 2-component elastomeric sealing polymer system designed to act as a crack filler primarily in concrete. This material provides exceptional adhesion characteristics and fast cure times. It is highly chemical resistant, insensitive to water, abrasion resistant and remains thermally stable in a range of -20°F (-29 C) to 250°F (125 C). It may be used under traditional floor coatings or any of our top-coating materials. Joint Seal is used in heavy traffic warehouse floors, refrigeration floors, chemical spill prone floors, pothole road repair or under ceramic tile floors. It meets FDA regulations for indirect food contact (CFR 21, Sec. 175-300).

Joint Seal is a 2-component elastomeric sealing polymer system designed to act as a crack filler primarily in concrete. This material provides exceptional adhesion characteristics and fast cure times. It is highly chemical resistant, insensitive to water, abrasion resistant and remains thermally stable in a range of -20°F (-29 C) to 250°F (125 C). It may be used under traditional floor coatings or any of our top-coating materials. Joint Seal is used in heavy traffic warehouse floors, refrigeration floors, chemical spill prone floors, pothole road repair or under ceramic tile floors. It meets FDA regulations for indirect food contact (CFR 21, Sec. 175-300). -

MACE-Flex

Mace-Flex is an aliphatic 1-component self-crosslinking waterborne formulation delivering excellent chemical and water resistance while providing good abrasion resistance and fast-setting properties.

Mace-Flex or Mace-Regular is designed to be solvent-free and used as a tough exterior topcoat, sealer or as an underlying penetrating primer. The penetrating nature of this material promotes its use for direct topcoating on porous and non-porous substrates masonary, wood, non-glazed tile, stucco, metal, composites and certain polymers. These materials may also be used as a primer in many SuperSkin System’s coating applications.Mace is an air-dry system where it is normally spray or roll applied. This low viscosity dispersion dries clear and flexible in 10-15 minutes acquiring full-cure in 24 hrs or maybe forced dried at elevated temperatures. Mace-Flex provides up to 200% elongation with a tensile strength of 2400 psi. Acrylic color pigments and thickener additives may also be included to enhance its widely diversified use.

-

MACE-Hard

MACE-Hard is an aliphatic 1-component waterborne formulation delivering excellent chemical and water resistance while providing good abrasion resistance and fast-setting properties. MACE-Hard is also available without solvent. This material is designed to be used as a tough exterior topcoat, sealer or as an underlying penetrating primer. The penetrating nature of these materials promotes its use for direct topcoating on porous and non-porous substrates masonry, wood, non-glazed tile, stucco, metal, composites and certain polymers. This material may also be used as a primer in many SuperSkin System’s coating applications. MACE-Hard is an air-dry system where it is normally spray or roll applied. This low viscosity dispersion dries clear in 10-15 minutes acquiring full-cure in 24 hrs or maybe forced dried at elevated temperatures. Acrylic color pigments and thickener additives may also be included to enhance its widely diversified use.

-

MACE-Hard-SF

Mace-Hard-SF is an aliphatic 1-component waterborne formulation delivering excellent chemical and water resistance while providing good abrasion resistance and fast-setting properties. MACE Hard is also available without solvent Mace-Hard-SF and both are designed to be used as a tough exterior topcoat, sealer or as an underlying penetrating primer. The penetrating nature of these materials promotes its use for direct topcoating on porous and non-porous substrates masonary, wood, non-glazed tile, stucco, metal, composites and certain polymers. This material may also be used as a primer in many SuperSkin System’s coating applications. Mace-Hard is an air-dry system where it is normally spray or roll applied. This low viscosity dispersion dries clear and flexible in 10-15 minutes acquiring full-cure in 24 hrs or maybe forced dried at elevated temperatures. Acrylic color pigments and thickener additives may also be included to enhance its widely diversified use.

-

MACE-Regular

Mace-Regular is an aliphatic 1-component self-crosslinking waterborne formulation delivering excellent chemical and water resistance while providing good abrasion resistance and fast-setting properties.

Mace-Regular is designed to be solvent-free and used as a tough exterior topcoat, sealer or as an underlying penetrating primer. The penetrating nature of this material promotes its use for direct topcoating on porous and non-porous substrates masonary, wood, non-glazed tile, stucco, metal, composites and certain polymers. These materials may also be used as a primer in many SuperSkin System’s coating applications.

Mace-Regular is an air-dry system where it is normally spray or roll applied. This low viscosity dispersion dries clear and flexible in 10-15 minutes acquiring full-cure in 24 hrs or maybe forced dried at elevated temperatures. Mace-Flex provides up to 200% elongation with a tensile strength of 2400 psi. Acrylic color pigments and thickener additives may also be included to enhance its widely diversified use.

-

Pole-Setting Rigid Foam

Pole Setting Foam is designed specifically for fast-setting structural pole-setting applications such as utility/telephone poles, flag poles, fence posts, etc. It is a tough 100% solids non-hydrophilic 6 pcf foam formulation exhibiting 100 psi compressive strength to provide secure fast-installations. The foam may be used directly in holes which contain a water volume of less than 5% of the total hole volume. It delivers excellent chemical resistance and may be applied in dirt having a wide pH range. For special applications a 9.0 PCF density is also available with the same characteristics, but higher compression strength.

Pole-Setting Foam is mixed 1:1 using a hand-held drill jiffy mixer until both components mix into a uniform color (approx 1min). It is then poured directly around the pole into the surrounding hole which obtains a firm material set-up within 15 minutes. The foam may be covered with dirt immediately after it becomes rigid to the touch. It will not be damaged by rain after this point. Material reactivity time may be adjusted to accommodate specific demanding application environments if requested. Please contact Customer Service/ Tech Support for application recommendations and procedures.