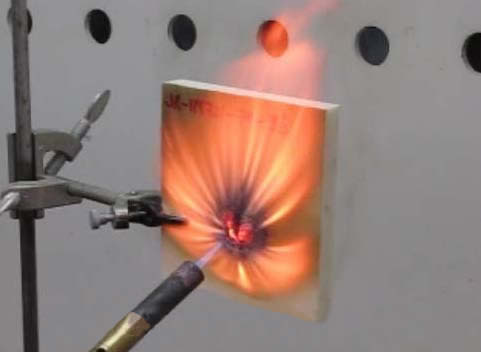

FireSkin™ Foam 0.5

Quick Overview

Fireskin Foam 0.5 is a two component, 1-1 parts by volume, light density, spray applied polyurethane foam. To produce Fireskin Foam 0.5 requires the use of an A-Component (ISO) and a B-Component (RESIN), which contains zero ozone depleting blowing agents, catalyst, polyols and flame-retardant materials such as fiberglass, cellulose or other loose fill products. Typical areas where spray polyurethane foam is applied are interior walls, attics, ceilings and spa insulations.

Technical Application Data

Fireskin Foam 0.5 should be processed through commercially available, two-component, heated, spray equipment designed for that purpose. Primary heat and hose heat for spray equipment should both be set at 130°F with machine pressure at 1,500 psi. Fireskin Foam 0.5 should only be applied by a qualified professional applicator. It is the responsibility of the professional applicator to thoroughly understand all equipment, technical information and safe operating procedures that pertains to a spray polyurethane foam application

Health and Safety

Read the Safety Data Sheet (SDS) and container labels for detailed health and safety information. This product is intended for industrial use by properly trained professional applicators only.

Physical Properties

| FIRESKIN™ FOAM 0.5 PHYSICAL PROPERTIES | ||

|---|---|---|

| R-Value | ASTM C518 | 3.8 @ 1″ |

| Core Density | ASTM D1622 | 0.5 lbs./ft.³ |

| Open Cell Count | ASTM D6226 | >97% |

| Sound Transmission Coefficient | ASTM E413 | 42 |

| Water Vapor Transmission – Permeance | ASTM E96 | 21 perms @ 1” |

| Air Leakage Rate | ASTM E283 | <0.02 (L/s-m2) |

| Noise Reduction Coefficient | ASTM C423 | 0.10 |

| Tensile Strength (PSI) | ASTM D1623 | 5.19 |

| Dimensional Stability | ASTM D2126 | <5% |

| Flame Spread | ASTM E84 | Class I < 20 |

| Smoke Development | ASTM E84 | Class I <400 |

Call TechSupport Group for assistance with using a SSS application system. Also read the Application Page on this website. It is always best to perform a test area section of the SSS material system to an exact application area prior to full scale engagement.

This technical data information is accurate to the best of our knowledge. SuperSkinSystems™ Inc. makes no warranty, expressed or implied within the materials on this website, its use or with its any application. SuperSkinSystems™ Inc. shall not be liable for material or application related injuries, material non-conformance, application failures or any consequential damage by the use of this product.

Reviews

There are no reviews yet.