BlastSkin II – Mine Safety

Quick Overview

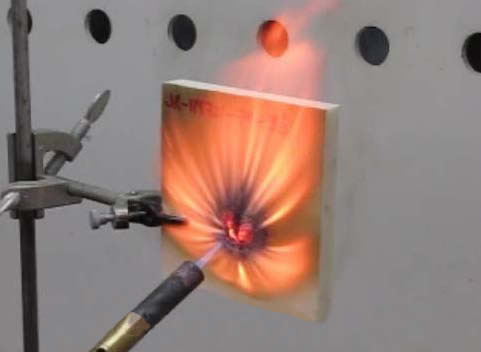

BlastSkin II- Mine Surface Protection System is a very strong super-polymer coating system designed to provide structural support while shielding against water and methane infiltration for all surfaces in the mine. This system provides high chemical, abrasion resistance, low fire and smoke meeting Class 1 ASTM E84, MSHA ASTM E162, Radiant Panel testing and MSHA IC-249 Flame resistance of solid products. The BlastSkinII protection system effectively delivers increases load bearing capacity and reduces localized failure points to defend against rupture and bursting. This high-strength composite structure provides added protection to mine workers, framework infrastructure and overall mine safety.

Mine Surface Protection System:

- Inject LeakStop into all surface cracks and voids.

- Spray structural FireSkin™ Foam (10 pcf) on mine surfaces (25mm).

- Apply BlastSkinII super-polymer over the structural FireSkin Foam (3mm to 6mm).

- Apply GlowSkin striping to walls (0.5mm).

Technical Application Data

BlastSkin II is a two component 100% solids formulation which does not contain VOCs. Skin thickness has no limitation. BlastSkinII must be applied using a 2-component 1500-1800 psi high-pressure liquid pumping heated spray machine. Material and line temperatures may vary but usually initially targeted at 140°F. Thorough mixing of the B-Side component is required during application. Proper safety wear is mandatory. Surface application temperature ranges from 0°F to 150°F with surface dry. Spray cure time 2-5s. Surfaces must be prepped for cleanliness and dryness and requires the use of an adhesion promoter primer to acquire proper adhesion. Functional material operation temperature ranges from -40°F to 250°F. Final top-coat appearance is glossy and slick to the touch. This material will not flow-out or lay-down. Spray coverage at 16 mils is 100 sq. ft./ mixed gal thickness.

Physical Properties

| BlastSkin II Physical Properties | |||

|---|---|---|---|

| Tear Strength | ASTM D624 | 500 lbs/ linear in. | |

| Impact | ASTM D2794 | >350 in. lbs | |

| Tensile Strength | ASTM D412 | 5411 psi | |

| Elongation | ASTM D412 | 250 % | |

| Hardness -Shore D | ASTM D2240 | 65 | |

| Abrasion -Taber CS17 | ASTM D4060 | 22 mg/1k cycles | |

| Gel Time | Time | 30 s | |

| Mix Ratio | PBV | 1:1 | |

| FireSkin (10pcf) Physical Properties | ||

|---|---|---|

| Fire Rating | ASTM E84 | Class 1 |

| Compression Strength (psi) | ASTM D1621 | 201 |

| Tensile Strength (psi) | ASTM D1623 | 227 |

| Water Absorption 24 hr (%vol) | ASTM D2842 | <0.1 |

| Thermal Resistance (R-value) | ASTM C518 | 4 |

| Flexular Strength (psi) | ASTM C203 | 312 |

| Closed Cell Content (%) | D2856 | >95 |

| Water Vapor (perm-in) | ASTM E96 | <1.0 |

Adhesion Results

Adhesion Results of Typical Substrates per ASTM D-4541 Elcometer

| Rock/Concrete- Primed | >300 psi | Cohesive failure; excellent bonding |

| Steel- Primed | >1000 psi | Excellent bonding |

| Wood- Primed | >250 psi | Wood failure; excellent bonding |

This technical data information is accurate to the best of our knowledge. SuperSkinSystems™ Inc. makes no warranty, expressed or implied within the materials on this website, its use or with its any application. SuperSkinSystems™ Inc. shall not be liable for material or application related injuries, material non-conformance, application failures or any consequential damage by the use of this product.

Reviews

There are no reviews yet.