FireSkin™ Foam

Quick Overview

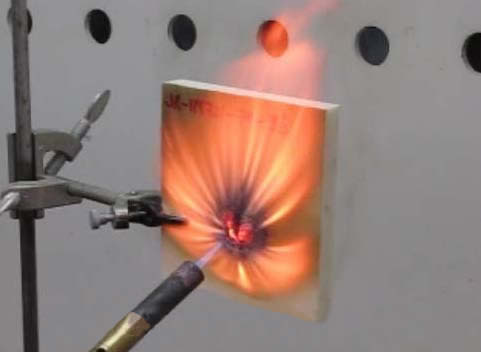

FireSkin Foam is an insulating material designed to withstand direct flame contact. It produces very low smoke and flame spread. The material develops an intumescent fire barrier which provides a protective shield against constant flame and extreme heat conduction to interior surfaces. These closed cell foams range in varing densities from 0.5-50 pcf for use in diverse fire protection system applications. FireSkin Foam is formulated as a Halogen-free, Class 1 fire rated foam containing renewable resource “Green” materials.

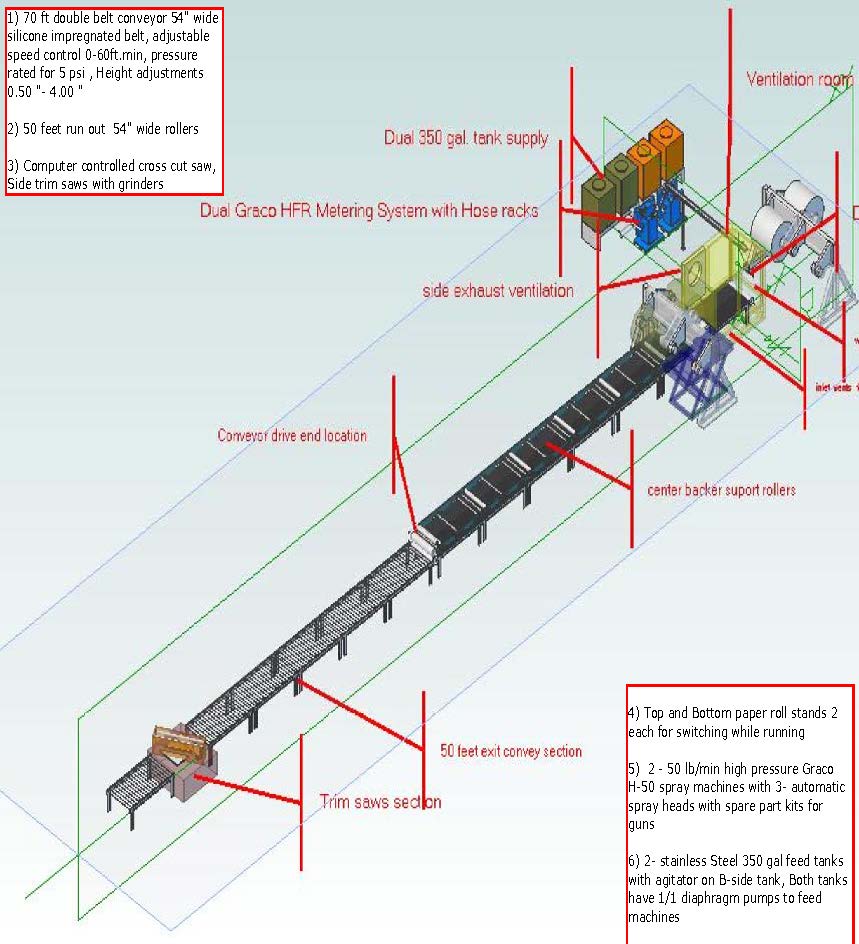

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here.

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here.

Technical Application Data

FireSkin™ Foam is a two component 100% solids spray formulation which does not contain VOCs. This material may require the use of a primer to obtain proper adhesion on certain substrates. All surfaces must be clean and free of contaminates and no moisture. Application temperature ranges from 50°F to 120°F. Gel Time may be adjusted to fit application. Typically, gel is 8-10 sec at 75°F with full cure in 24 hours. Use standard 1:1 high pressure plural component spray machine such as Graco EXP2. Functional operation temperature ranges from -40°F to 300°F. Application spray thickness should be based on continuous build. Foam coverage depends directly density, temperature of substrate, material and ambient conditions.

Physical Properties

| FIRESKIN™ FOAMS PHYSICAL PROPERTIES | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| DENSITY (PCF) | ASTM D1622 | 1.5 | 1.75 | 2.0 | 2.5 | 3.0 | 4 | 6 | 10 |

| Fire Rating | ASTM E84 | Class 1 | Class 1 | Class 1 | Class 1 | Class 1 | Class 1 | Class 1 | Class 1 |

| Thermal Resistance (R value) | ASTM C518 | 5.5 | 6.0 | 6.5 | 6.5 | 6.5 | 6.0 | 5.0 | 4.0 |

| Compressive Strength (psi) | ASTM D1621 | 15 | 19 | 25 | 37 | 50 | 82 | 140 | 201 |

| Shear Strength (psi) | ASTM C273 | 17 | 20 | 22 | 26 | 30 | 35 | 85 | 127 |

| Shear Modulus | ASTM C273 | 207 | 224 | 231 | 253 | 280 | 312 | 788 | 1011 |

| Tensile Strength (psi) | ASTM D1623 | 25 | 35 | 40 | 44 | 52 | 62 | 165 | 227 |

| Flexual Strength (psi) | ASTM C203 | 40 | 45 | 50 | 56 | 90 | 123 | 204 | 312 |

| Flexual Modulus | ASTM C203 | 164 | 330 | 522 | 963 | 1400 | 2356 | 4785 | 7055 |

| Water Absorption 24 hr (%vol) | ASTM D2842 | <0.5 | <0.5 | <0.5 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| Water Vapor (perm-in) | ASTM E96 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Fungi Resistance | ASTM C 1338 | None | None | None | None | None | None | None | None |

| Closed Cell Content (%) | ASTM D2856 | >80 | >85 | >90 | >90 | >95 | >95 | >95 | >95 |

Adhesion Results

| Adhesion Results of Typical Substrates per ASTM D-4541 Elcometer | ||

|---|---|---|

| Concrete- Primed | >300 psi | Concrete cohesive failure; excellent bonding |

| Steel- Primed | >1000 psi | Excellent bonding |

| Wood- Primed | >300 psi | Wood failure; excellent bonding |

Call TechSupport Group for assistance with using a SSS application system. Also read the Application Page on this website. It is always best to perform a test area section of the SSS material system to an exact application area prior to full scale engagement.

This technical data information is accurate to the best of our knowledge. SuperSkinSystems™ Inc. makes no warranty, expressed or implied within the materials on this website, its use or with its any application. SuperSkinSystems™ Inc. shall not be liable for material or application related injuries, material non-conformance, application failures or any consequential damage by the use of this product.

Reviews

There are no reviews yet.